Aerospace Division

Advanced processing technology and cutting edge facilities for optimal manufacturing

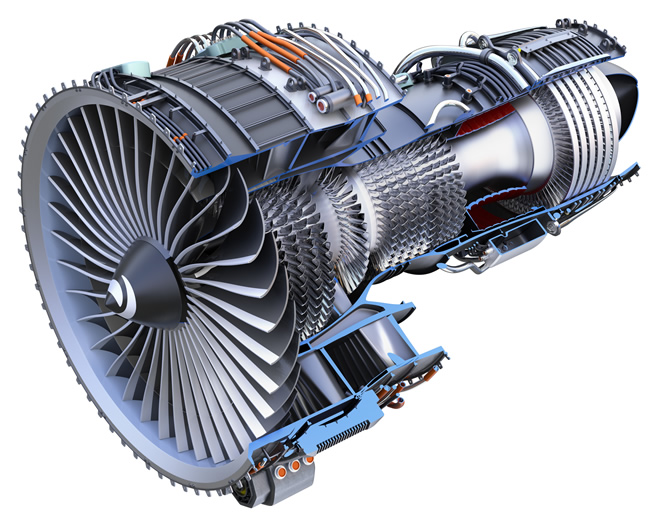

We manufacture engine parts for aircraft and rockets.

We respond to customer needs by performing integrated production from material procurement to parts production, quality assurance, and delivery.

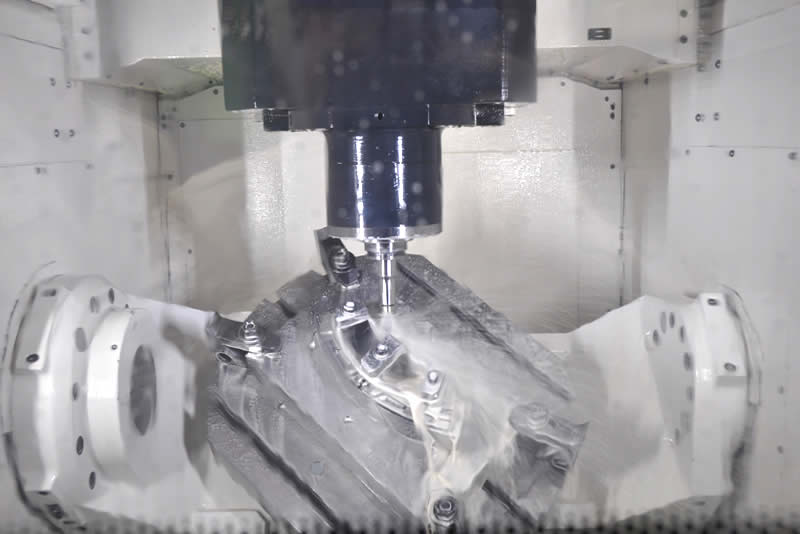

In addition, by combining deformation processing and machining using cutting edge facilities with the skilled handwork techniques we have cultivated over many years, we work on processing projects that meet the quality and technical difficulty that our customers require.

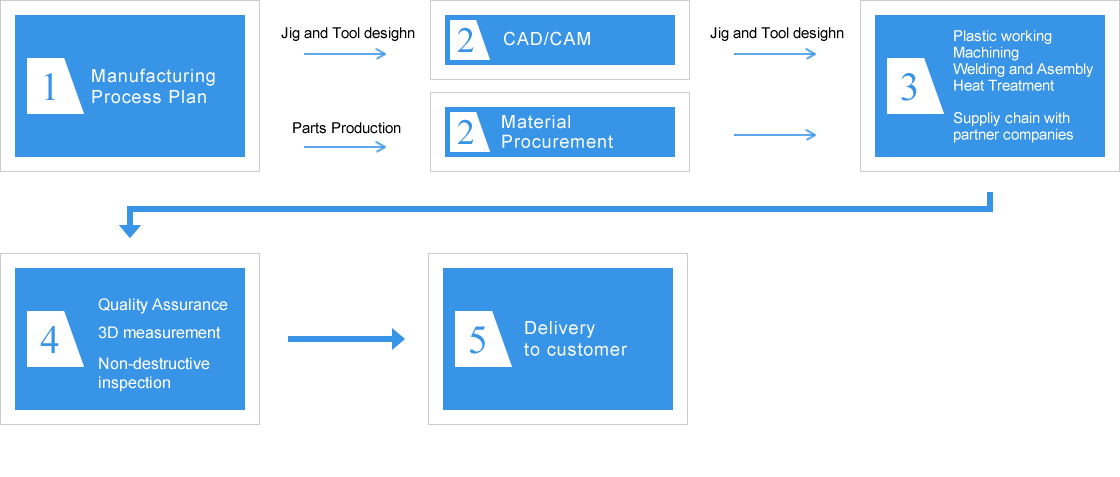

Integrated production system

Based on comprehensive production management from the design and production of jigs, tools, to the production of parts, we plan a manufacturing process plan and materialize products with an integrated production system.

In component manufacturing, we deliver products through various processing processes, including material procurement through our supply chain, while guaranteeing the quality that meets customer requirements.

Main technology

Main technology

- 3D tool desigh and Forming Anaysis

- Hot/Cold Press, Expand Forming

- Machining jig design

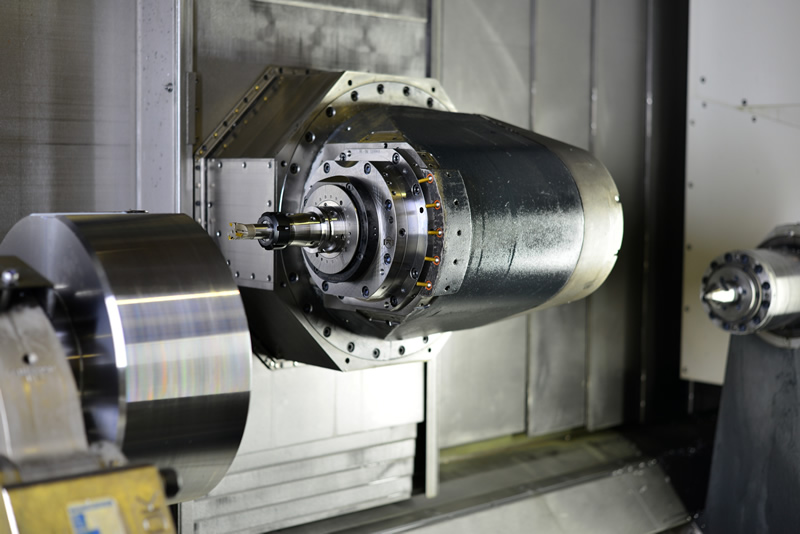

- CNC Programming

- 5 Axis CNC Milling and Turning

- Fiber laser processing

- Wire EDM cutting

- Assemble jig design

- TIG Welding (Nadcap certified)

- Fiber laser welding

Plastic working

Machining Technology

Assembly technology

Quality Assurance

- 3-D measurement (Contact, Non-contact)

- Surface Roughness Measuremnt

- Contour measurement

- Fluorescent Penetrate Inspection (Nadcap Authentification)

- X-ray inspection

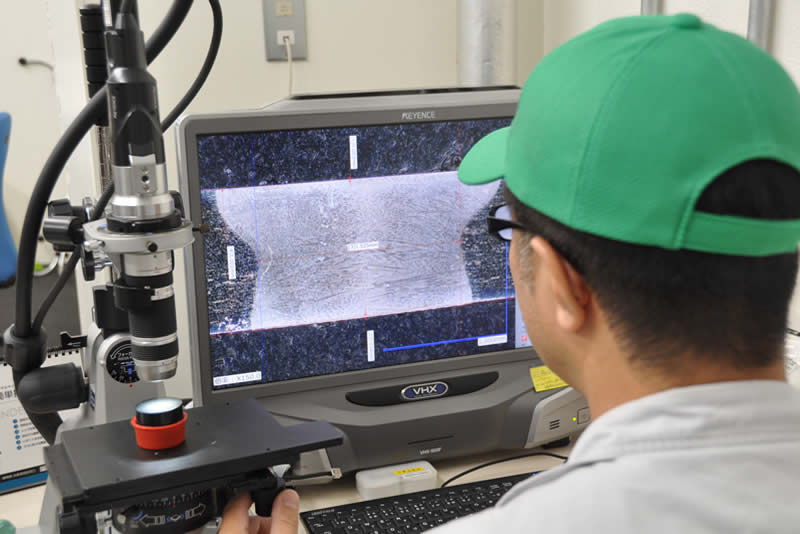

- Microscopic Examination

- Weld inspection /Welding deposition Inspection

- Leak Test

- On the jig inspection

Dimentional property

Configuration characteristic

Non-destructive inspection

Metallographic evaluation

Others

Feel free to contact for a Technical consultation /quote.

Kousaku Terashita, Deputy Manager

Aero / Space sales section

Phone:+81 82-235-2030+81 82-235-2030

FAX:+81 82-235-2050