Technologies introduction

Tecnology development

We take actions aggresively to pursue developing our own original technologies, including the development of new processing technologies and new material application technologies.

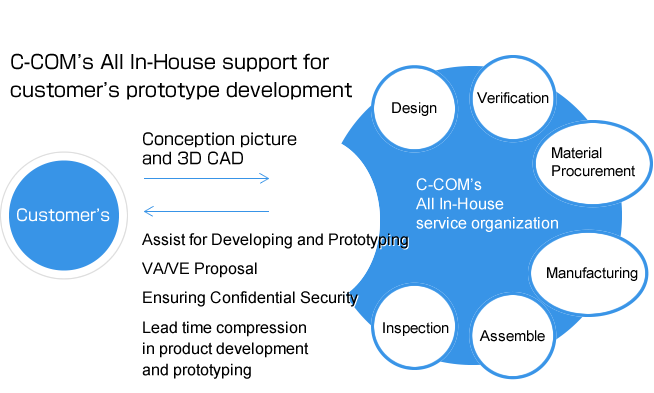

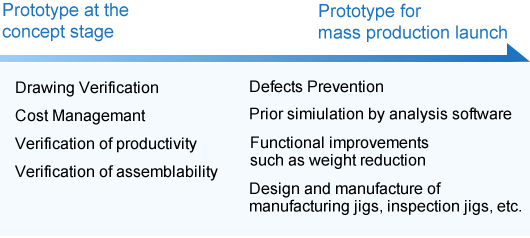

All In-House support for prototype development

We provide prototype support from the concept stage with request from customer.

We support prototype development from various aspects such as Forming analysis, Die concept, and Jig concept.

We also make VA / VE proposals based on our experience, as needed.

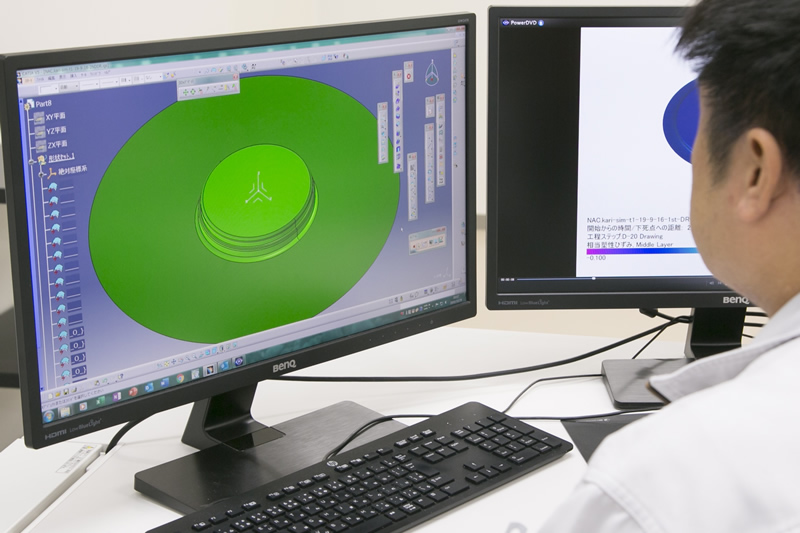

Design and processing technology

We have an in-house integrated production system from design to machining, pressing, welding, heat treatment, assembly, and inspection.

By conducting development and prototyping under an Integrated production system, we carry out measures to troubleshoot for mass production launch and various preliminary verifications.

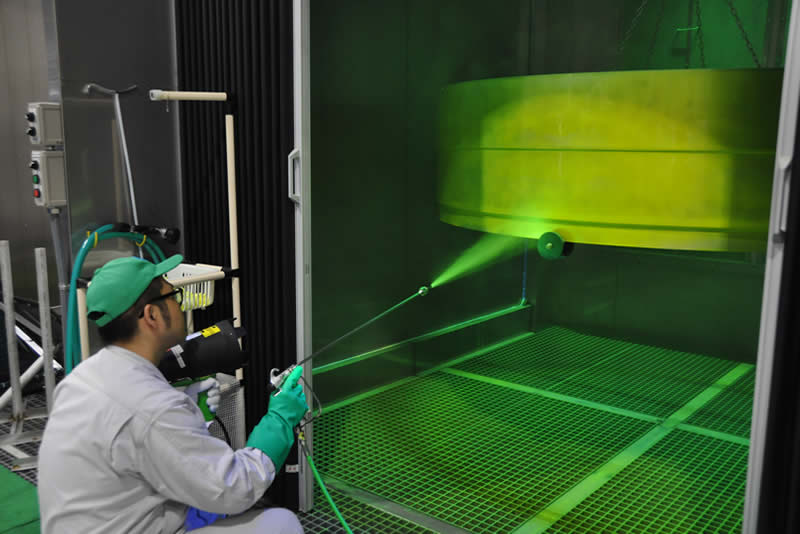

Various inspection, verification and quality assurance systems

We have obtained JISQ9100 certification and Nadcap certification and have established a global standard quality assurance system.

In addition, we perform various inspections and tests in-house for design and feasibility verification required at the development and prototype stages, and provide timely feedback to customers.

Various design verification

- Forming Simulation

- Macroscopic Examinations

- Mechanical characteristic Test

Vairous Inspections

- 3D Measurement

- Non-destructive inspection

- Surface roughness inspection

Main Market and Production example

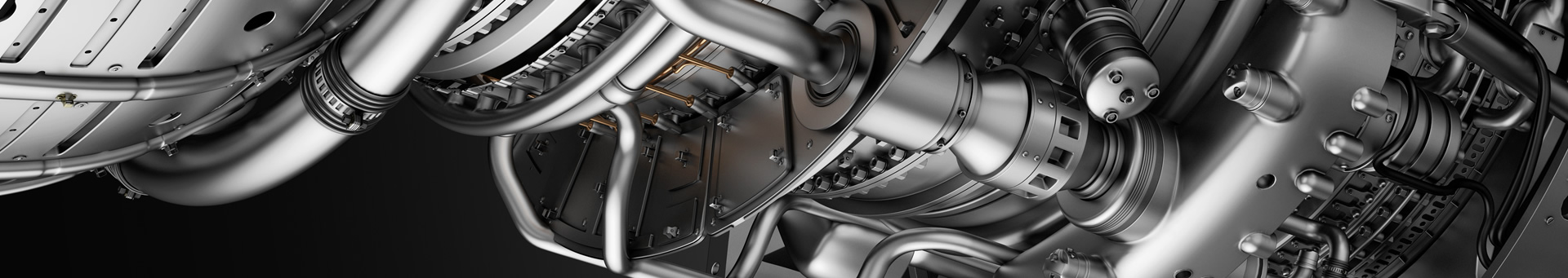

Aerospace

- Aircraft Engine Components

- Gas Turbine Parts

- Rocket Engine Parts

Energy・Industrial Machinery

- Underground LNG tank panel

- Vessel Engine Parts

- Power Plant Engine Parts

Automotive

- BIW(Body in white)

- Roof Panel

- Fender

- Hood/Bonnet

- Side Door

- Trunk

- Suspension Member

- Steering Member

- Floor Panel

- Cut Model for Exhibition

Construction Equipment

- Forklift parts

- Aguricultural Tractor parts

- Small Excavator parts

- Hydraulic Excavator Parts

- Wheel loader cabin

Railcar

- Half dome forming metal work of Shin-kan-sen header

- Pantograph cover

- Exhaust duct for air conditioniner

Semiconductor manufacturing equipment

- Vacuum Chanmber

- Exhaust Air Duct

- Frame case

Feel free to contact for a Technical consultation /quote.

Koji Tanabe, Senior General Manager

Machinery & Motor vehicle division

Phone:+81 82-249-4450+81 82-246-7578

FAX:+81 82-246-7578