Machinery & Motor vehicle division

We assist our customers' prototype development

to small-lot mass production

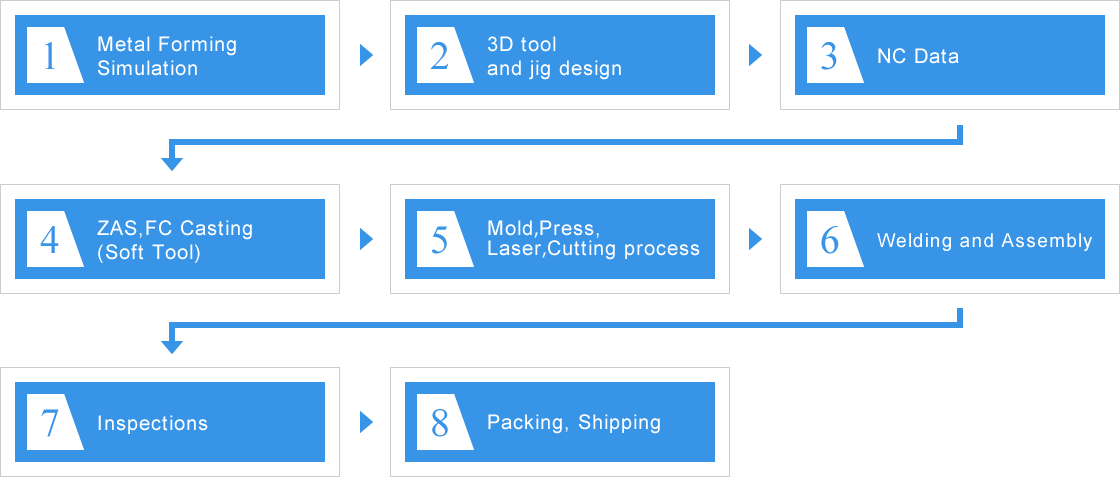

From prototype development to small-lot mass production, we have worked on various projects as a development and prototyping factory for each manufacturer with an integrated production system.

We can also assist customers with small lot mass production parts, from the product concept stage to prototype development for launching mass production.

Wide items range from sheet metal parts to machined parts.

We work with customers globally, from domestic manufacturers to overseas manufacturers, and respond to a variety of customer requests.

C-COM's production system aims to shorten

development lead times and improve costs

by leveraging an integrated production system

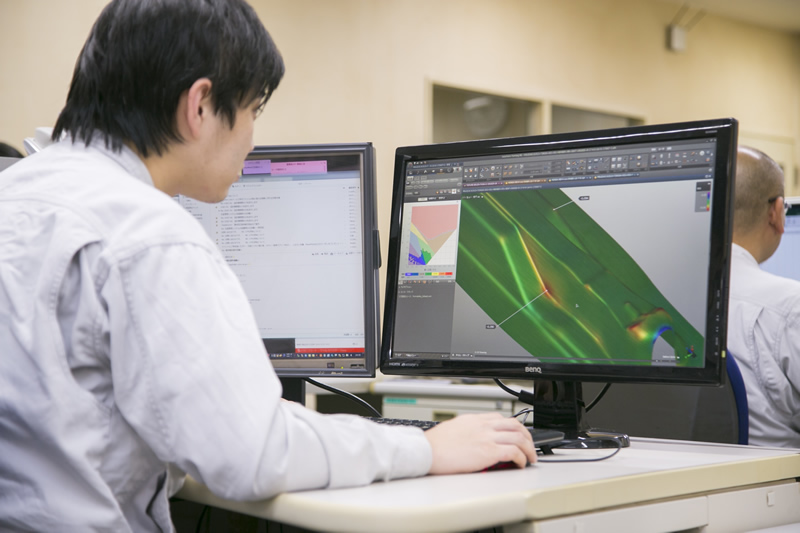

By conducting repeated examinations in SE activities and various simulations, and making 3D prototypes, we are consistently examining structures, shapes, and process designs that are difficult to judge with 2D drawings.

Main technology

Main technology

- Press simulation analysis

- Resin 3D printer model verification

- Prototype Dies (Soft Tool) Design and ZAS/FC Casting

- NC Milling of Press Dies

- Design and production of welding, clinching, and hemming jig

- Design and manufacture of prototype inspection jig

- Reverse Engineering

- Deforming process of ultra high tensile strenght steel sheet

- Die Quench Process

- Hot Pressing

- 2D/3D Laser Process

- Large 5 axis machining process

- Large turning process

- B.I.W build

- Aluminium body assembly (SPR, Self Piercing rivet)

- Laser Brazing Weld Robot

- Spot welding robot and MIG welding robot

- Roller Hemming Process

Production Engineering

Parts Manufacturing

Unit Assebly

Quality Assurance

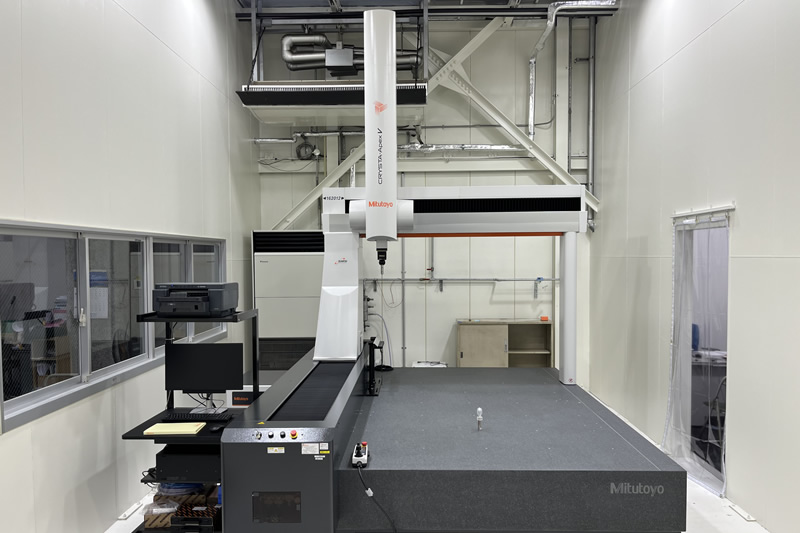

- FARO, 3D CMM, contact type

- 3D Scanning System, non-contact type (Color map)

- Leak Tester

- Welding Tensile Test

- Macro electron microscope examination of welding

- Diffusion layer coating test

- Spot weld test (Ultrasonic)

- Hardness Measurement

- Surface Roughness Measuremnt

Measurement

Testing Equipment

Feel free to contact for a Technical consultation /quote.

Koichi Matsumoto, Manager

Phone:+81 82-249-4450+81 82-249-4450

FAX:+81 82-246-7578